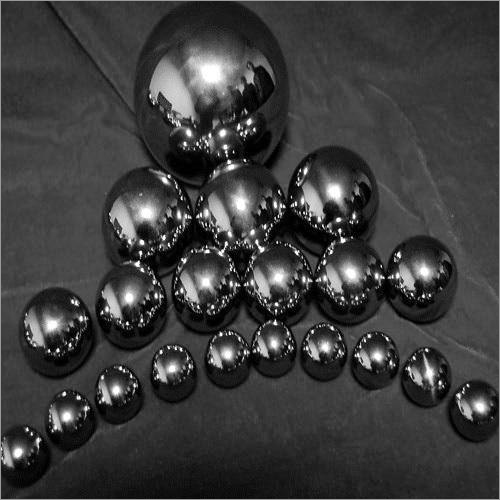

Stainless Steel Balls For Grinding

MOQ : 25 Kiloohms

Stainless Steel Balls For Grinding Specification

- Hardness

- 55-65 HRC

- Size

- 2 mm to 80 mm

- Product Type

- Stainless Steel Grinding Balls

- Material

- Stainless Steel

- Steel Grade

- AISI 304, AISI 316, AISI 420, AISI 440C

- Diameter

- 2 mm to 80 mm

- Thickness

- Standard as per ball diameter

- Surface

- Polished, Smooth

- Weight

- Varies according to size

- Color

- Silver

- Standards

- ASTM, DIN, JIS

- Density

- 7.8 g/cm³

- Life Cycle

- Long Service Life

- Manufacturing Process

- Cold/Hot Forged, Heat Treated

- Magnetic Properties

- Depends on steel grade

- Tensile Strength

- Up to 850 MPa

- Usage Environment

- Dry and Wet Grinding

- Packaging Type

- Drum, Bag, Customized

- Corrosion Resistance

- Excellent

- Shape

- Spherical

Stainless Steel Balls For Grinding Trade Information

- Minimum Order Quantity

- 25 Kiloohms

- Main Domestic Market

- All India

About Stainless Steel Balls For Grinding

Our company is actively involved in offering a wide stock of the highest grade Stainless Steel Balls For Grinding to widely scatted valuable patrons. At our state of the art production facilities, these kinds of balls are precisely designed and fabricated from top of the line stainless steel material in perfect round shape, white color, and grade of 200 series with developed casting technology. Rust proof, robust, smooth finishing and long life, clients can get Stainless Steel Balls For Grinding in 25kg drum packaging at economical prices.

| Material Grade | SS |

| Grade | 200 series |

| Material | Stainless Steel |

| Shape | Round |

| Packaging Type | Drum |

| Color | White |

Precision Construction & Superior Materials

Our stainless steel grinding balls are crafted from premium AISI 304, 316, 420, and 440C grades, ensuring excellent durability and consistent grinding efficiency. Engineered through cold/hot forging and advanced heat treatments, each ball exhibits superior hardness and strength, delivering reliable performance in both dry and wet processes.

Corrosion Resistance and Robust Performance

Featuring exceptional resistance to corrosion, these grinding balls are ideal for chemical processing, paints, cement, mining, and other industrial milling applications. Their polished, smooth surfaces and compliance with global standards like ASTM, DIN, and JIS make them a trusted choice for heavy-duty environments.

Custom Sizing and Flexible Packaging

Available in a wide array of sizes from 2 mm to 80 mm, our stainless steel balls meet diverse usage requirements. Packaging options include drums, bags, and customized solutions, catering to manufacturers, suppliers, exporters, and traders across India and beyond.

FAQ's of Stainless Steel Balls For Grinding:

Q: How are stainless steel grinding balls manufactured?

A: Stainless steel grinding balls are produced through cold or hot forging followed by precise heat treatment. This process enhances their hardness (55-65 HRC) and tensile strength (up to 850 MPa), ensuring reliable performance across various grinding applications.Q: What types of applications are these grinding balls suitable for?

A: These balls are versatile and designed for use in grinding media, industrial milling, chemical processing, paints, cement, and mining industries. Their corrosion resistance makes them ideal for both dry and wet operational environments.Q: When should I choose a particular stainless steel grade for grinding balls?

A: Select stainless steel grades based on your application's chemical and mechanical requirements. For example, AISI 316 offers superior corrosion resistance, while AISI 440C provides higher hardness. The grade also determines magnetic properties and wear resistance.Q: Where can these stainless steel grinding balls be used?

A: These balls are widely employed in facilities and industries that operate ball mills, sand mills, or agitators for material processing, such as in mining, cement plants, chemical factories, and paint manufacturing units.Q: What are the benefits of using polished and smooth surface balls?

A: Polished and smooth-surfaced balls minimize wear on milling equipment, reduce contamination risk, and enhance grinding efficiency by ensuring uniform contact and energy transfer during operation.Q: How does the packaging of these balls ensure safe transportation and storage?

A: The grinding balls are packaged in drums, bags, or custom solutions to protect them from damage and contamination. This ensures safe handling, transportation, and storage, tailored to customer specifications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

SYNCO INDUSTRIES LIMITED

GST : 08AAACS5548J1Z2

GST : 08AAACS5548J1Z2

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS