Vibratory Finishing Ceramic Media

Vibratory Finishing Ceramic Media Specification

- Application

- Surface Finishing, Deburring, Polishing, Cleaning

- Molecular Weight

- Variable (Depending on Composition)

- Product Type

- Vibratory Finishing Ceramic Media

- Melting Point

- Approximately 1600C

- Storage

- Store in Dry Area, Avoid Moisture

- Density

- 2.8 Gram per cubic centimeter(g/cm3)

- Shelf Life

- Indefinite (if stored dry)

- Shape

- Triangular, Cylindrical, Spherical, or Custom

- Ph Level

- Neutral (6.5 - 7.5)

- HS Code

- 69149000

- Smell

- Odorless

- Molecular Formula

- Al2O3 + SiO2 + Binder

- Purity

- High Grade (>99%)

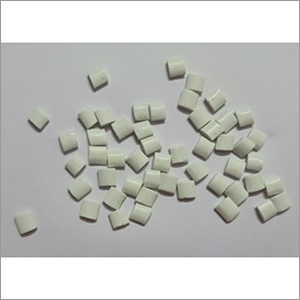

- Appearance

- Greyish White

- Grade

- Industrial Grade

- Usage

- Used in Vibratory Finishers, Tumblers for Metal and Plastic Parts

- Solubility

- Insoluble in Water

- Physical Form

- Solid

- Other Names

- Polishing Ceramic Media, Deburring Media

- Poisonous

- NO

- Bulk Density

- 1.6 - 2.0 g/cm³

- Particle Size Range

- 2mm to 60mm

- Packing Details

- 25Kg or 50Kg HDPE Bags / Jumbo Bags

- Service Temperature

- Up to 800°C

- Color

- Grey, White, or Custom

- Customization

- Available as per Customer Specification

- Resistant to Acid & Alkali

- Yes

- Hardness (Mohs)

- 7 - 9

- Abrasive Type

- Medium/High

- Surface Finish Type

- Matt, Glossy or Satin depending on Media Selection

- Toxicity

- Non-toxic

- Impact Strength

- High

Vibratory Finishing Ceramic Media Trade Information

- Main Domestic Market

- All India

About Vibratory Finishing Ceramic Media

Our years of experience in this sector has enabled us to put forward the best quality Vibratory Finishing Ceramic Media. Ideal for polishing, cleaning, radiusing, and de-rusting applications, this type of media is made up of selected grade ceramic material in white color, and polished finishing with developed technology in adherence with industry standards. Highly effective, free from adulterants, durable, and long life, clients can get Vibratory Finishing Ceramic Media in all sizes, and shape like triangle angle cut, cylindrical, star, etc.

| Brand | Synco Industries |

| Color | White |

| Finishing | Polished |

| Material | Ceramic |

| Usage/Application | polishing, radiusing, cleaning and de-rusting |

| Pack Type | Packet |

Superior Abrasive Performance

Our ceramic media delivers reliable medium to high abrasive capabilities, ensuring efficient deburring, cleaning, and polishing for diverse metal and plastic components. The high impact strength and adjustable particle sizes allow for tailored finishing performance in industrial applications.

Customizable Shapes & Surface Finishes

Choose from triangular, cylindrical, spherical, or custom shapes to suit specific application demands. Select between matt, glossy, or satin finishes by adjusting media specification for optimal aesthetic and functional results.

Safe, Durable, and Eco-Friendly

Manufactured with high-grade (>99%) purity and neutral pH, this media is non-toxic, odorless, and insoluble in water. Resistant to acid and alkali, it provides a durable solution with an indefinite shelf life when stored in dry conditions.

FAQ's of Vibratory Finishing Ceramic Media:

Q: How is vibratory finishing ceramic media used in surface finishing of metal or plastic parts?

A: Vibratory finishing ceramic media is placed inside vibratory finishers or tumblers along with workpieces. The media abrasively grinds, polishes, deburrs, and cleans surfaces, achieving desired finishes such as matt, glossy, or satin depending on the selected media type.Q: What are the main benefits of using this ceramic media for industrial finishing processes?

A: This ceramic media offers consistent abrasive action, high impact strength, and excellent hardness, enabling precise material removal and superior surface improvement. Its resistance to acid, alkali, and water ensures longevity and safe operation, with customizable sizes and shapes allowing tailored finishing solutions.Q: When should I choose medium or high abrasive type for my finishing requirements?

A: Select medium abrasive type for gentle deburring and surface smoothing, ideal for sensitive materials or fine finishes. High abrasive type is recommended for aggressive material removal and rapid cleaning where faster results or heavier deburring is required.Q: Where is this ceramic media typically manufactured and exported from?

A: This product is manufactured, supplied, and exported from India by leading industrial exporters, manufacturers, suppliers, and traders. It is conveniently packed in HDPE bags or jumbo bags for international and domestic dispatch.Q: How do I ensure proper storage and maintain shelf life for ceramic media?

A: Store the ceramic media in a dry area, away from moisture, to preserve its integrity. Since it is non-toxic and has an indefinite shelf life if kept dry, no special environmental controls are required beyond avoiding dampness.Q: Is customization available for particle size, color, and shape according to project specifications?

A: Yes, customization is available for particle size, shape (triangular, cylindrical, spherical, or custom), and color to meet specific customer or project requirements, enabling optimized surface finishing outcomes.Q: What processes can this ceramic media be applied to other than vibratory finishing?

A: While primarily designed for vibratory finishers and tumblers, the ceramic media is also suitable for use in cleaning, polishing, and deburring operations across various industrial sectors requiring durable and effective surface treatments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vibro Finishing Beads Category

10 MM Porcelain Straight Cut Trister Finishing Media

Other Names : Ceramic Tumbling Media, Deburring Media

Shelf Life : Unlimited under Suitable Conditions

Storage : Other, Store in Dry Area, Away from Acids and Chemicals

Density : 2.6 Gram per cubic centimeter(g/cm3)

Physical Form : Solid

Product Type : Porcelain Straight Cut Trister Finishing Media

10X10 MM Porcelain Straight Cut Triangle Finishing Media

Other Names : Porcelain Deburring Media, Ceramic Tumbling Media

Shelf Life : Unlimited under recommended storage conditions

Storage : Other, Keep dry and avoid contamination

Density : 2.40 Gram per cubic centimeter(g/cm3)

Physical Form : Solid

Product Type : Porcelain Straight Cut Triangle Finishing Media

MM Porcelain Straight Cut Eclipse Finishing Media

Other Names : Porcelain Media, Ceramic Tumbling Media

Shelf Life : Long, reusable under proper conditions

Storage : Other, Store in a dry, cool place away from moisture

Density : 2.35 Gram per cubic centimeter(g/cm3)

Physical Form : Solid

Product Type : Porcelain Straight Cut Eclipse Finishing Media

6X12 MM Porcelain Straight Cut Cylinder Finishing Media

Other Names : Porcelain Deburring Media, Porcelain Tumbling Media

Shelf Life : Long shelf life under proper storage

Storage : Other, Store in a dry, clean place

Density : 2.3 Gram per cubic centimeter(g/cm3)

Physical Form : Solid

Product Type : Porcelain Straight Cut Cylinder Finishing Media

GST : 08AAACS5548J1Z2

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS